Miljövänlig uppvärmning

Gas, värmepump, sol, el eller olja

Vilken värmekälla är optimal för dig?

Spara 20% på din uppvärmningskostnad

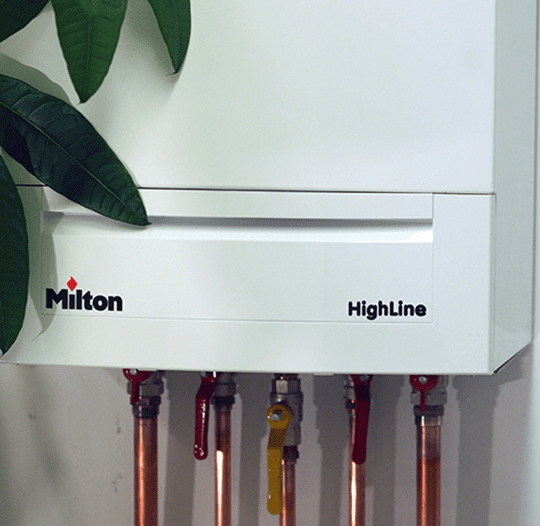

Du får kostnadseffektiv uppvärmning med kondenserande gaspannor från Milton. Vi anpassar effekten efter ditt värmebehov och återvinner energin i avgaserna. Det minskar energiförbrukningen och därmed dina uppvärmningskostnader. Verkningsgraden för kondenserande gaspannor överstiger 100 % under drift, vilket innebär att värmesystemet är både effektivt och energisnålt.

Garanti utöver det vanliga

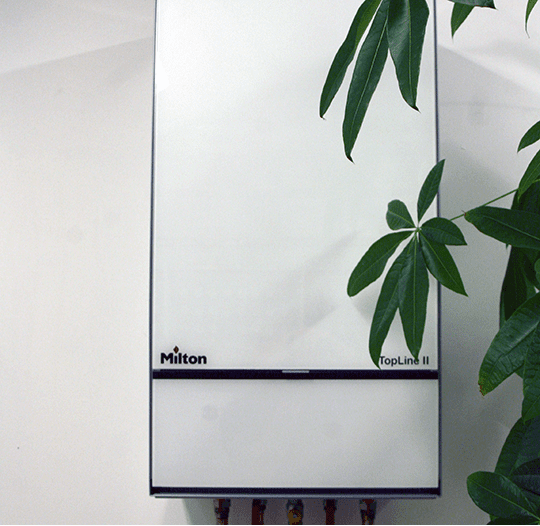

Du får hela 15 års garanti på värmeväxlaren i Milton TopLine, SmartLine och EcomLine-pannor när du använder Miltons serviceteam. Vi kan med säkerhet leverera marknadens bästa garanti, då vår skickliga serviceavdelning har mycket god produktkännedom.

Se våra produkter

Dyk ner i våra produktkataloger och ta reda på mer om dina värmealternativ

Den direkta vägen till bättre värme

Vi hjälper dig hela vägen

Är du intresserad av en offert, ett besök eller bara ett samtal om din värmeanläggning, är du alltid välkommen att

3.400

Glada servicekunder

ROT

Få rabatt när du köper miljövänligt

Staten ger ekonomisk ersättning via ROT-avdrag och har dessutom ersättningshjälp till dig som investerar klimatvänligt.

50 +

års erfarenhet

Vi har jobbat med värme sedan 1972. De många års erfarenhet tar vi med oss när vi ger råd om den bästa värmelösningen för just dig.

Ett bra inomhusklimat är grunden för en hemtrevlig miljö

Sveriges bästa värmeerbjudande

Milton Topline ger dig stabil, miljövänlig och ekonomisk trygghet. Så ska riktig uppvärmning vara, oavsett om värmekällan är värmepump, olja, gas, el eller sol.

Våra produkter är utvalda från de bästa leverantörer och omfattar de flesta typer värmeinstallationer.